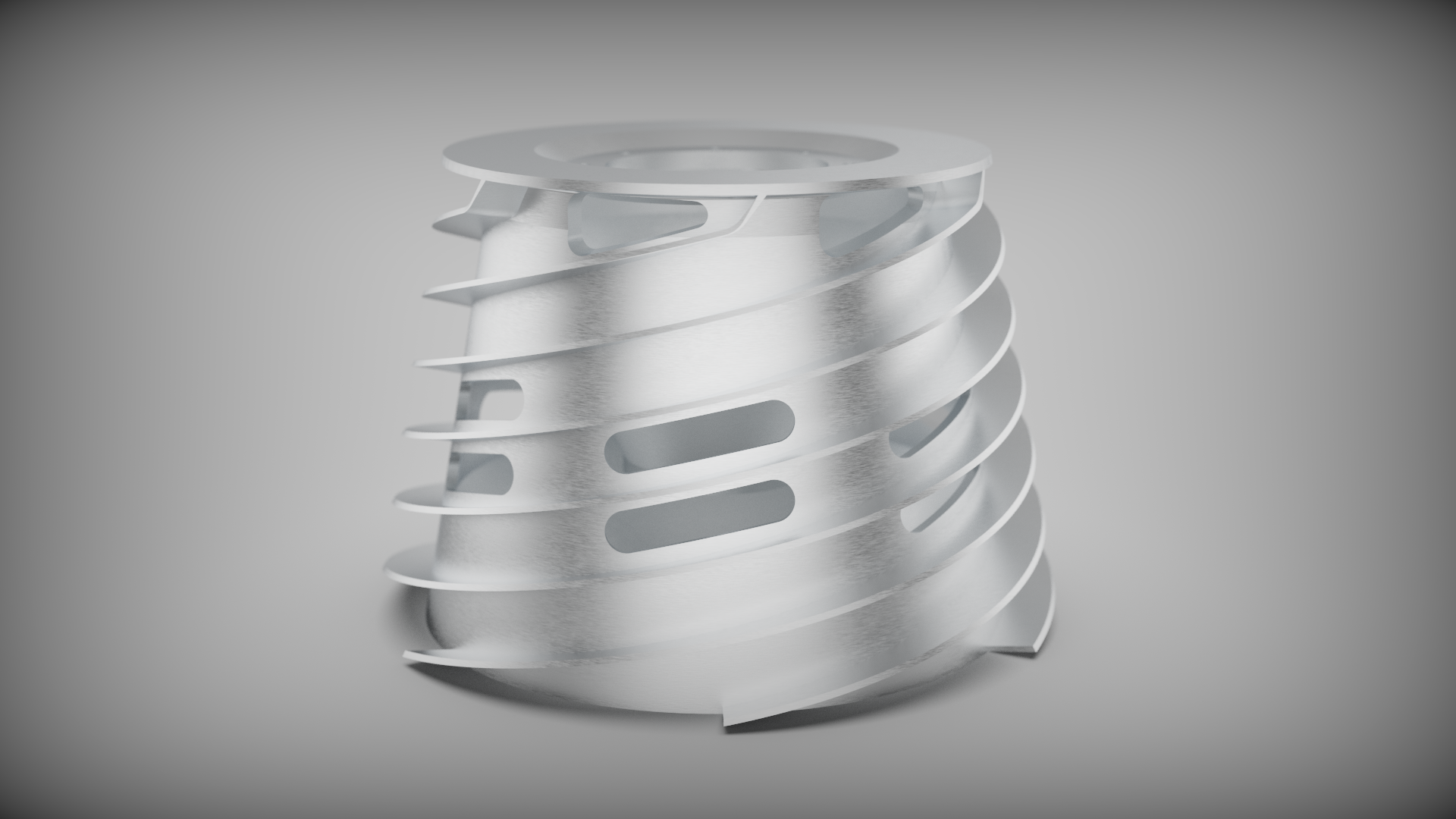

A scroll wheel that needed modifications done in order to ensure proper functionality and increase longevity.

Project Details

- Client: Anonymous

- Category: Fabrication, 3D Laser Scanning

- Tools: Dassault Solidworks, Keyshot, AutoCAD

Metrology instruments were used to verify the dimensional accuracy of the scroll wheel. These dimensions were then used to reverse-engineer the wheel in Solidworks for use in design modification.

Jeff Joos, owner of Joos Fabrication and located in Washington Illinois, was able to provide the client with proper, clean TIG welding for the scroll wheel. After two years of use, the wear from the product had worn down the fins on the outer edge of the stainless steel. This was corrected by additional welds on the fins.

Problems were encountered in the original design of this wheel, such as buildup and wear. TWG implemented changes requested by the client to improve efficiency and prolong the lifespan of the part. The additional flights welded on the inside of the wheel improved product flow, gradual acceleration, and prevented buildup.